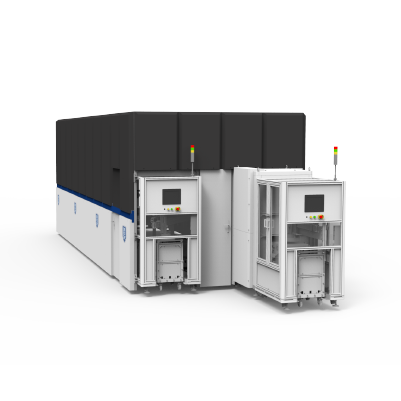

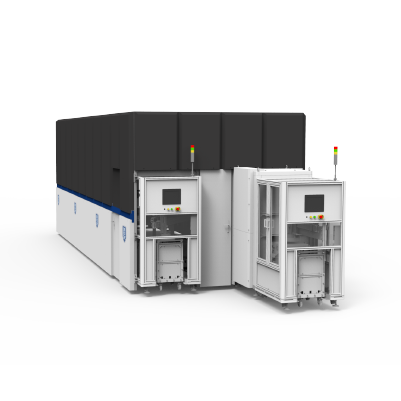

SMD BOX is the fully automatic storage hub at the heart of Neotel’s material management ecosystem. It handles storage, retrieval, and return — three of the six steps in the SMT material loop — across 11 purpose-built models. Whether you need a single-channel entry point or 10,000+ reel capacity, and whether you store standard reels, solder paste, moisture-sensitive devices, or totes, there is an SMD BOX built for the job.

SMD BOX sits at the center of the SMT material lifecycle, managing storage on inbound, work-order retrieval on outbound, and automatic return after counting. It is the most frequently used equipment in a fully automatic material workflow.

SMD BOX offers four capacity tiers — from a single-channel entry model to a 10,000+ reel flagship. Choose the model that fits your current throughput, then scale up or deploy in parallel as your operation grows. Your investment stays protected.

Built on the SMD BOX core platform, six scenario-specific models address everything from inline integration to solder paste storage and moisture-sensitive device management.

SMD BOX ONE integrates material registration, high-capacity storage, and precision counting into a single machine. One system covers every step of the material loop except production itself — maximum space efficiency, minimum process complexity, built for large-scale factories that want it all.

Match the right model to your line size and material types. Compare across the capacity line and scenario line below.

| Comparison | SISO | MIMO | DUO | XLR |

|---|---|---|---|---|

| Positioning | Entry-level single-channel | High-throughput multi-channel | Balanced dual-channel | Extra-large flagship storage |

| Channels | Single | Multi-channel parallel | Dual | Multi-channel |

| Storage Type | Standard reels | Standard reels | Standard reels | Standard reels |

| Recommended Scale | 1–2 lines / small batch | 3+ lines / high-frequency retrieval | 2–4 lines / medium-to-large | 5+ lines / centralized warehouse |

| Key Features | Smallest footprint, fast deployment | Parallel retrieval, highest throughput | Simultaneous dual-direction access | 10,000+ reel capacity, upgradeable to ONE |

| Integrated Registration / Counting | — | — | — | Upgradeable to ONE |

| Comparison | BOXi | HYBRID | XLC | SP | SPC | MSD | ONE |

|---|---|---|---|---|---|---|---|

| Positioning | Inline point-of-use storage | Mixed-format storage | Tote management | Solder paste storage | Solder paste lifecycle | MSD dry cabinet | All-in-one flagship |

| Storage Type | Standard reels | Reels + tubes + tape | Totes / bins | Solder paste jars | Solder paste jars | Moisture-sensitive devices | Standard reels |

| Recommended Scale | Per-line deployment | High-SKU mixed lines | Tote-level material mgmt. | All scales | High-compliance factories | Lines with MSD materials | 5+ lines / large factories |

| Key Features | Direct pick-and-place integration | Multi-packaging co-storage | Tote-level auto storage/retrieval | Refrigeration + rewarming + mixing | Traceability + alerts + IPC compliance | Floor Life tracking | Registration + storage + counting in one |

| Integrated Registration / Counting | — | — | — | — | — | — | Built-in auto registration and X-ray counting |

Neotel offers two parallel product lines based on your automation level and budget:

Fully automatic storage and retrieval, unmanned operation, built for large-scale lines and high-compliance factories. 11 models cover every scenario. Ideal when you need maximum efficiency, strict compliance, and have the budget for full automation.

Light-guided picking with manual handling — low investment, fast deployment, ideal for small-to-medium lines or factories transitioning to smart warehousing. The right choice when you want smart upgrades at lower cost.

Not sure which model fits? Our solution consultants will recommend the best configuration based on your line scale, material types, and automation goals.