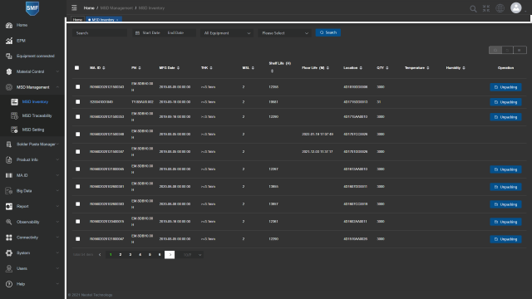

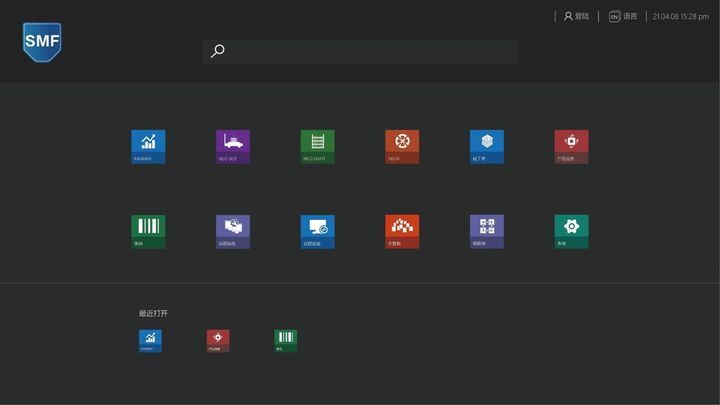

Remaining Component monitoring

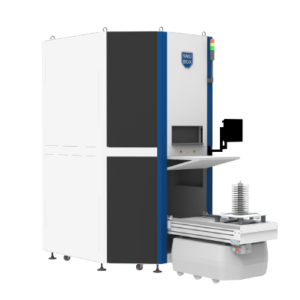

Production material can now be replenished with an automatic re-order system with the component level inventory monitoring from Neotel SMF. As currently loaded material in feeder locations get ‘low’ a pick request will be then generated. Smt tower will automate the material immediately.

Component Counts

Partly finished component is returned from the production line and it is important to update the component profile and know its latest quantity information. SMT tower system can receive information from Neo Counter, Xray Component Counter, developed by Neotel can seamlessly work together.