Home » Products

Revolutionizing electronics manufacturing with intelligent automation, precision tracking, and Industry 4.0 compliance

Comprehensive smart material management solutions designed for modern electronics manufacturing environments

Intelligent material identification and tracking system with advanced barcode/QR scanning capabilities for seamless electronics manufacturing workflows.

Advanced storage solution with automated retrieval, intelligent inventory management, and real-time component tracking for optimal efficiency.

Intelligent storage rack with LED guidance system, real-time monitoring, and seamless integration with manufacturing execution systems.

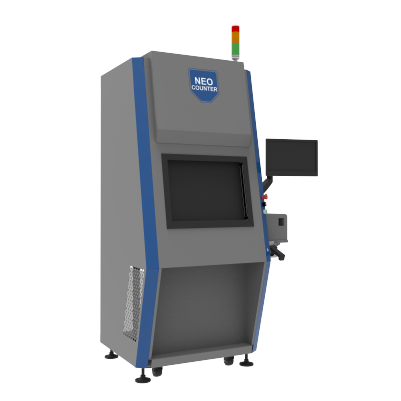

Precision X-ray counting system for accurate component verification, quality control, and inventory validation in semiconductor manufacturing.

Advanced features that set our solutions apart in the smart manufacturing landscape

Advanced reporting and analytics with real-time monitoring capabilities

Seamless integration with existing ERP and MES systems

Full compliance with Industry 4.0 standards and protocols

Intelligent automation with machine learning capabilities

System Uptime

Components Tracked

Global Installations

Support Coverage

Tailored solutions for diverse manufacturing environments

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Specialized solutions for surface mount technology and high-precision component placement.

Advanced tracking and management systems for semiconductor manufacturing processes.

Inventory management and tracking solutions for component distributors and suppliers.

Get in touch with our team to learn more about our smart material management solutions and discover how we can optimize your operations.