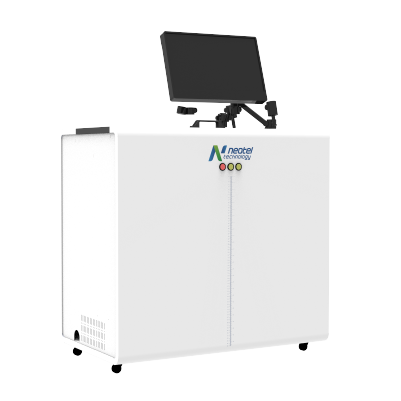

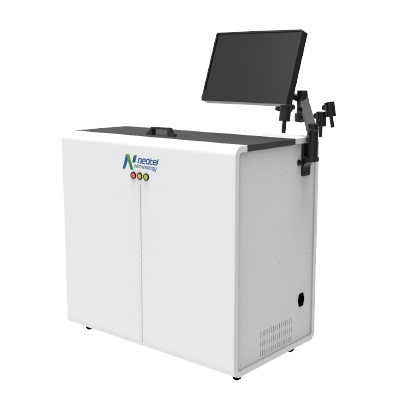

Advanced Ionic Contamination Testing for PCBs and Electronic Components

Flexibility to adopt both dynamic and static testing methods as per IPC standards, meeting diverse customer requirements without dual equipment investment.

Accurately measures ionic contamination levels by detecting conductivity changes caused by charged particles on PCB surfaces.

Fully compliant with IPC-TM-650 testing methods including ROSE test (2.3.25) and Ion Chromatography (2.3.28).

Ionic contamination is the presence of charged particles (ions) on electronic surfaces that can interfere with proper device functioning. These ions, introduced through dust, moisture, or pollutants, leave residues that can disrupt current flow, cause short circuits, or interfere with sensitive component operations.

Critical for aerospace, automotive, military, and telecommunications industries, contamination-free PCBs are mandatory for conformal coating, epoxy shaking, or underfill processes. Flux residue left on assemblies causes delamination and poor wetting, making cleanliness testing a routine quality control procedure.

| Testing Method | IPC TM-650 Reference | ||

|---|---|---|---|

|

Ion Chromatography |

Ion Chromatography |

||

|

SIR Testing for Materials |

IPC TM 650 2.6.3 Series |

||

|

Electromigration Test |

IPC TM 650 2.6.14 Series |

||

|

R.O.S.E. Testing |

IPC TM 650 2.3.25 |

||

|

Modified R.O.S.E. Testing |

IPC TM 650 2.3.25.1 |

μg/NaCl/cm² IPC Limit

Detection Accuracy

Dynamic & Static Methods

Continuous Testing

Join leading manufacturers in maintaining the highest cleanliness standards