Manual picking averages 45 seconds per reel and frequent errors cause costly line stoppages. NEO LIGHT uses pick-to-light guidance and position-sensing technology so operators no longer need to memorize thousands of bin locations — reducing single-pick time to 3 seconds and driving error rates well below 0.1%. Six models cover storage, retrieval, and return, delivering warehouse digitalization without any production-line modifications.

Across the full material lifecycle — from incoming receipt to post-production return — precise tracking at every step is critical. NEO LIGHT covers inbound storage, work-order retrieval, and post-production return, serving as the storage management hub throughout the material flow.

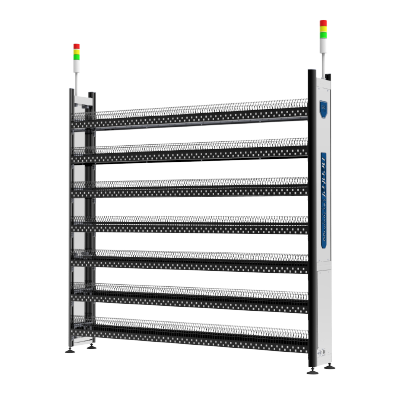

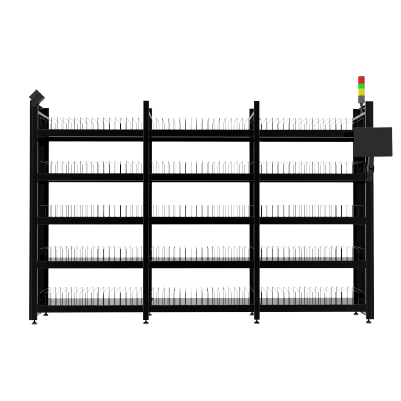

NEO LIGHT offers two dimensions of choice: picking technology and deployment mode. Pick-to-light or sensor-enhanced, stationary or mobile — select the combination that matches your line requirements.

For stencils and moisture-sensitive devices, NEO LIGHT provides dedicated solutions. No need to compromise on a general-purpose model for specialized material handling.

Compare key specifications across all six models to find the configuration that matches your line.

| Comparison | PTL | PLUS | Mobile | Mobile Plus | Stencil | MBB |

|---|---|---|---|---|---|---|

| Picking Technology | Pick-to-Light | Light + Position Sensor | Pick-to-Light | Light + Position Sensor | Position Sensor | Light + Position Sensor |

| Deployment | Stationary | Stationary | Mobile (casters) | Mobile (casters) | Stationary | Stationary |

| Inventory Confirmation | Manual barcode scan | Automatic sensor detection | Manual barcode scan | Automatic sensor detection | Automatic sensor detection | Automatic sensor detection |

| Material Types | SMT reels, trays | SMT reels, trays | SMT reels, trays | SMT reels, trays | SMT stencils | Moisture-sensitive devices |

| Typical Use Case | Standard line picking & kitting | High-compliance traceability | Multi-line sharing, flexible dispatch | Dynamic layouts, real-time tracking | Centralized stencil management | IPC/JEDEC moisture compliance |

NEO LIGHT and SMD BOX form a powerful co-deployment model: SMD BOX serves as the central warehouse for bulk material storage, while NEO LIGHT deploys as line-side shelving for workstation-level kitting. Connected through SMF software, inventory stays globally visible and materials flow between central and line-side storage on demand.

Light-guided picking with manual handling. Low investment, fast deployment — ideal for line-side kitting, small-to-medium lines, or flexible production scenarios.

Fully automatic storage and retrieval, unmanned operation — built for central warehouses, large-scale lines, and high-compliance factories.

Not sure which model fits? Our solution consultants will recommend the optimal configuration based on your materials, line layout, and efficiency targets.