MSD is Moisture-sensitive devices (MSDs) are electronic components encapsulated with plastic compounds and other organic materials. Moisture from atmospheric humidity enters permeable packaging materials by diffusion and collects at the interfaces of dissimilar material.

Moisture barrier bags, (sometimes called foil bags, alufoil bags or Mylar bags), are one of the most effective packaging solutions on the market today to protect against corrosive damage caused by humidity, moisture, oxygen, salt spray, aromas, grease and other airborne contaminants.

Moisture sensitivity level relates to the packaging and handling precautions for some semiconductors.

Neo Light MBB is powered by SMF software. SMF: Smart Material Flow is the software suite from Neotel Technology for controlling and automate electronics materials. It can cover all your materials needs: Materials receiving, Automated material storage/retrieval system, AGV control, Component counting, Kitting, etc.

Smart Material Flow software provide seamless integration to your existing IT system, ERP/SCM/MES/WMS. Through our advanced Connectivity service users could also connect external equipment, robot, etc.

Control movement of electronics component in and out in wherever stored at Neo Light/SMD BOX family. High data grain level material check-in/check-out time, work order reference, automated process start/end time, etc.

Make smarter decisions with real-time dynamic reports that you can save and share with anyone. Keep key information at your fingertips with custom dashboards.

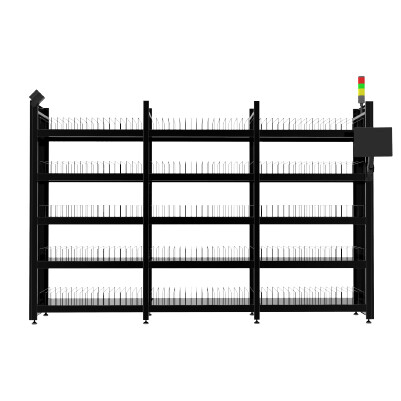

Storage capacity:

Wifi: Included

LAN:Included

Touch Screen: Option

Power:220v