After production, how many components remain on each reel? Manual estimation is slow and inaccurate, causing inventory records to drift from reality. NEO COUNTER uses X-ray penetration imaging combined with AI algorithms to count remaining components in seconds with 99.9% accuracy. Counting data syncs automatically to storage systems, ensuring return quantities are precise and trustworthy—closing the final link of the material loop. Two models cover semi-automatic offline to fully automatic inline operation for any production scale.

In the complete material cycle from registration to return, counting sits at a critical juncture—after production, before return. NEO COUNTER uses X-ray imaging to precisely count remaining quantities, providing reliable data for return and ensuring inventory records always match physical stock.

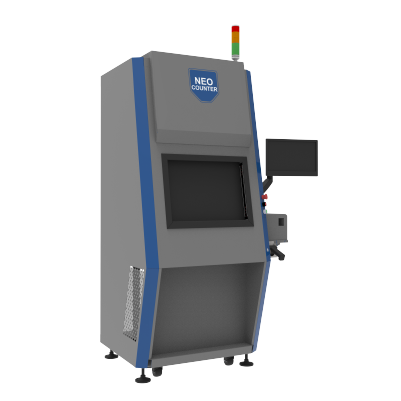

NEO COUNTER comes in two automation levels—X400 for standalone operation on small-to-mid production lines, X800 for full integration with SMT lines and AGV systems. Both share the same X-ray imaging + AI counting core, with unified data formats for seamless upstream and downstream connectivity.

The table below helps you quickly compare the core differences between X400 and X800. Choose the right model based on your line scale, automation level, and counting throughput requirements.

| Comparison | NEO COUNTER X400 | NEO COUNTER X800 |

|---|---|---|

| Automation Level | Semi-automatic (offline, manual operation) | Fully automatic (inline, unattended) |

| Loading Method | Manual placement (up to 4 reels) | Dual-track automatic loading/unloading |

| Counting Speed | 5–10 seconds per reel | Continuous high-speed, up to 1,200 reels/hour |

| Accuracy | 99.9% | 99.9% |

| X-Ray Imaging | High-resolution penetration imaging | High-resolution penetration imaging |

| AI Algorithm | NeoX Standard | NeoX Advanced (cloud analytics) |

| Barcode Reading | Built-in camera system | Industrial camera auto-recognition |

| Data Management | Local storage + USB export | Cloud real-time sync + intelligent analytics |

| System Integration | API integration with ERP / MES | Full ERP / MES / WMS / AGV integration |

| Line Integration | Standalone, flexible deployment | Embedded in SMT line, AGV-connected |

| Registration Device | NEO SCAN | NEO SCAN PLUS |

| Storage Device | NEO LIGHT Smart Shelf | SMD BOX Smart Storage |

| Typical Scenario | Small-to-mid batch, R&D prototyping, urgent orders | High-volume lines, 24/7 continuous production |

After counting, remaining materials carry precise quantity data back to storage. Inventory records update automatically with no manual entry—the material loop closes completely, ready for the next retrieval cycle.

After X800 high-speed counting, AGV automatically transports materials back to SMD BOX. Return quantities and inventory records reconcile automatically—fully unattended, loop completely closed.

After X400 offline counting, operators place materials back on NEO LIGHT. LED guides direct to the correct slot, sensors confirm placement, and inventory updates automatically.

Not sure whether X400 or X800 fits your needs? Our experienced consultants will recommend the best counting system and ecosystem based on your line scale, counting frequency, and automation goals.