Dry cabinet

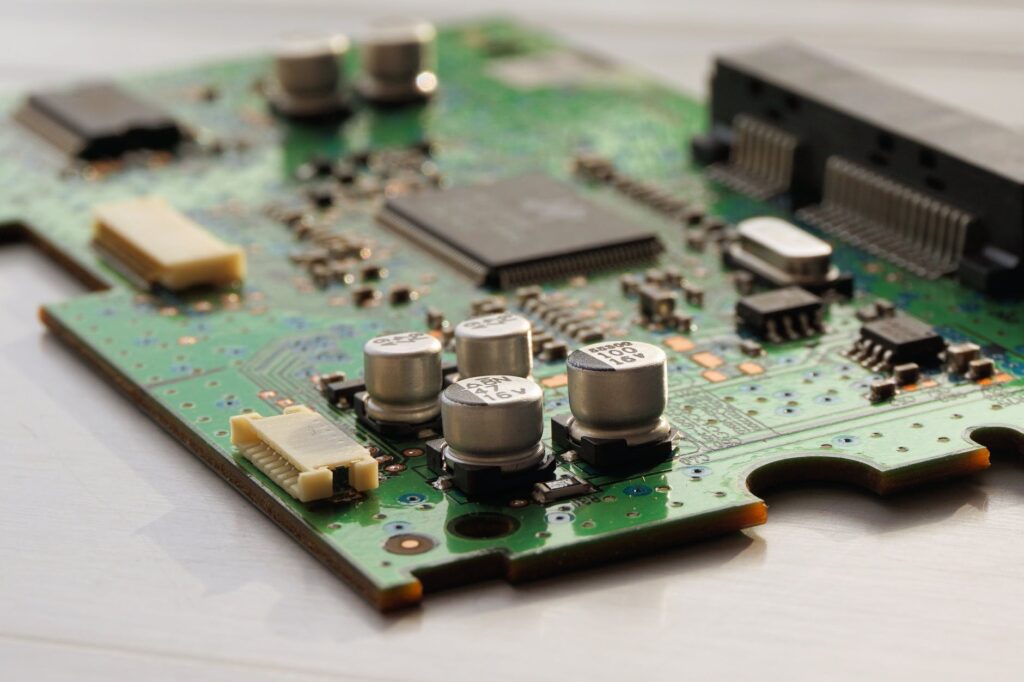

A dry cabinet is a storage cabinet that protects electronic components from moisture and humidity. These cabinets are typically used to store sensitive electronic components, such as printed circuit boards and other electronic assemblies, that are sensitive to changes in humidity and temperature. Dry cabinets maintain a controlled, low-humidity environment inside the cabinet, typically through a desiccant or other moisture-absorbing material. This helps to prevent corrosion and other moisture-related damage to the stored components. Dry cabinets are commonly used in electronics manufacturing and repair facilities, as well as in research and development labs and other settings where electronic components need to be stored in a controlled environment.

Temperature control

Temperature control for electronic component storage is maintaining a consistent, optimal temperature range in the storage environment to protect electronic components from temperature-related damage. Electronic components are sensitive to temperature changes, and exposure to extreme or rapid temperature changes can cause them to malfunction or fail. To protect electronic components from temperature-related damage, it is essential to control the temperature in the storage environment and keep it within a specific range.

Several factors can affect the temperature of a storage environment for electronic components, including the ambient temperature, the level of insulation, and the presence of heat-generating equipment. To maintain a consistent temperature in the storage environment, it may be necessary to use air conditioning or heating, insulation, and other temperature-control measures. It is also essential to monitor the temperature regularly to ensure that it stays within the optimal range.

The optimal temperature for electronic components

The optimal temperature range for storing electronic components will depend on the specific components being stored and their temperature sensitivity. Generally, it is recommended to store electronic components at a temperature of around 25°C (77°F) with a relative humidity of around 50%. However, some components may require a narrower temperature range or a different humidity level. It is essential to consult the manufacturer’s specifications for the specific components stored to determine their optimal temperature range.

Humidity control

Humidity control maintains a consistent, optimal humidity level in the storage environment for electronic components. Electronic components are sensitive to changes in humidity, and exposing them to high or low humidity levels can cause them to malfunction or fail. To protect electronic components from humidity-related damage, it is essential to control the humidity in the storage environment and keep it within a specific range.

Several factors can affect the humidity of a storage environment for electronic components, including ambient humidity, ventilation level, and moisture-generating equipment. To maintain a consistent humidity level in the storage environment, it may be necessary to use a dehumidifier or humidifier, ventilation, and other humidity-control measures. It is also essential to monitor the humidity regularly to ensure it stays within the optimal range.

The optimal humidity range for storing electronic components will depend on the specific components and their humidity sensitivity. It is recommended to store electronic components at a relative humidity of around 50%. However, some components may require a more narrow humidity range. It is essential to consult the manufacturer’s specifications for the specific components stored to determine their optimal humidity range.

Vacuum packaging for electronic components

Vacuum packaging can protect electronic components from moisture and other environmental factors that can cause damage. When vacuum packaging electronics, choosing suitable materials and packaging methods is essential to ensure that the components are adequately protected. Some factors to consider when choosing vacuum packaging materials for electronics include the following:

- Permeability: The packaging material should effectively block the penetration of moisture, oxygen, and other gases.

- Compatibility: The packaging material should not react with the electronic components or outgas any chemicals that could damage the components.

- Durability: The packaging material should withstand the mechanical stresses of transportation and handling without tearing or degrading.

- Ease of use: The packaging process should be quick and easy, with minimal risk of damage to the components.

J-STD-033

J-STD-033 is a standard developed by the Joint Electron Device Engineering Council (JEDEC) that describes the requirements for moisture/reflow sensitivity classification for surface mount devices (SMDs). It specifies the conditions under which SMDs must be tested to determine their sensitivity to moisture and the effects of soldering processes on their reliability. The standard also provides guidelines for labelling and storing moisture-sensitive SMDs to ensure their reliability and proper handling during manufacturing.

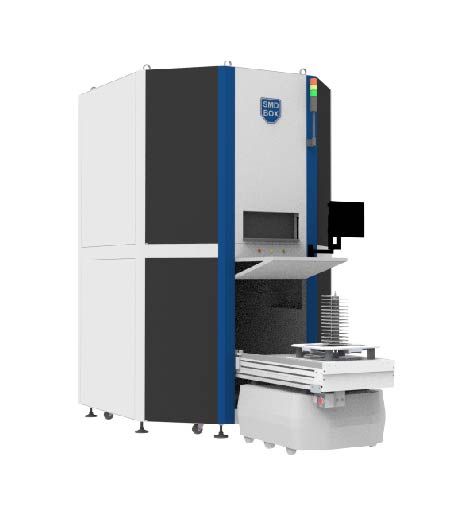

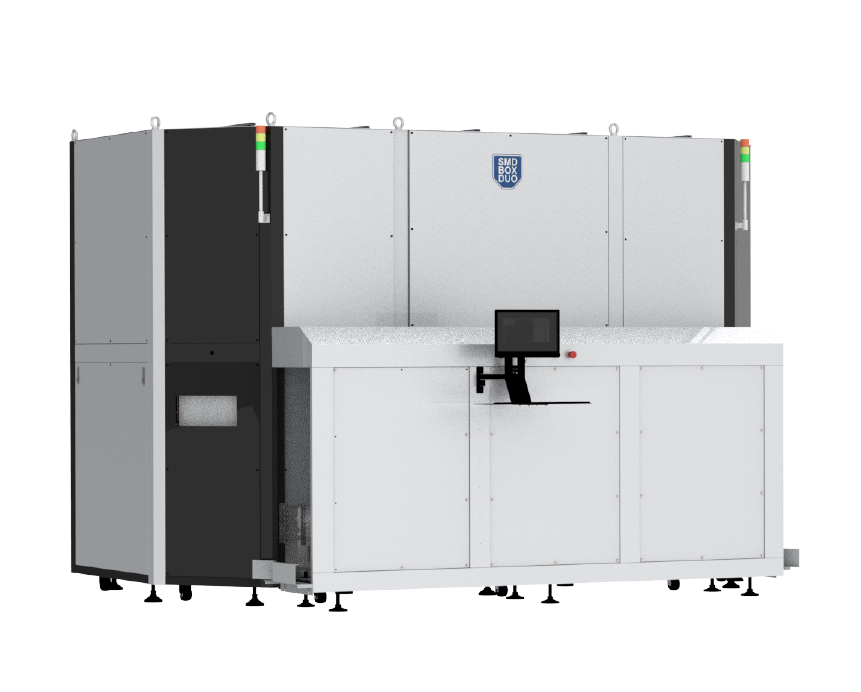

Automated dry warehousing

Here are several reasons why automating electronic material storage can be beneficial:

- Improved accuracy and efficiency: Automating material storage can help to improve accuracy and efficiency by reducing the need for manual handling and tracking of materials. This can help to reduce errors and improve the overall flow of materials within the storage facility.

- Enhanced security: Automated storage systems can help to improve security by controlling access to materials and tracking movements within the facility.

- Increased capacity: Automated storage systems can often store more materials in a smaller footprint, increasing the overall capacity of the storage facility.

- Reduced labour costs: Automating material storage can help to reduce labour costs by minimizing the need for manual handling and tracking of materials.

- Improved safety: Automating material storage can help to improve safety by reducing the risk of accidents and injuries related to manual handling and tracking of materials.

Overall, automating electronic material storage can help to improve the efficiency, accuracy, security, capacity, and safety of the storage process, leading to cost savings and other benefits.