Manual through hole assembly risks and challenges

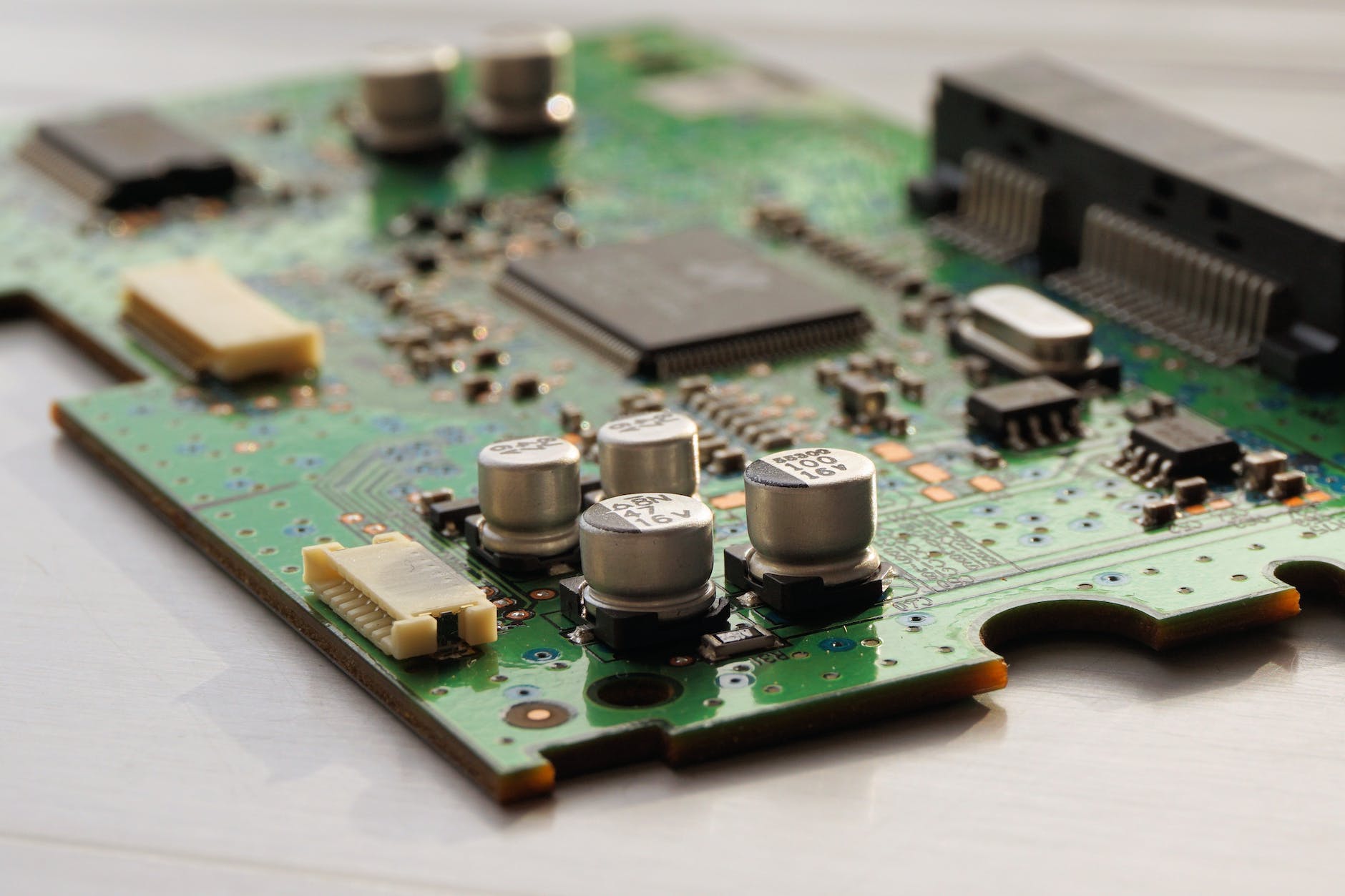

Manual through-hole technology, darling, is a quaint method of assembling electronic devices. It involves manually inserting components into holes drilled in a printed circuit board and then soldering them. It’s like fitting puzzle pieces together, only with a soldering iron.

The main challenge with this technique is the risk of human error, such as misalignment of components, improper insertion, or soldering. These errors can lead to the malfunctioning of the device or even complete failure, which can be quite a bummer. Additionally, manual through-hole technology is a time-consuming and labour-intensive process, which can be costly in terms of both time and money.

Another risk associated with manual through-hole technology is the potential for repetitive strain injuries to the operators assembling the PCBs. This is because manually inserting and soldering components can be physically demanding and cause strain and injury if not performed correctly.

Projector-guided assembly station

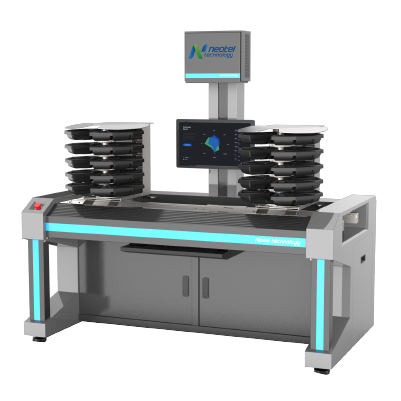

Projector-guided assembly is a manufacturing process in which a projector displays images or diagrams on a work surface. The worker uses these images as a guide to assemble the product. This can be used in various electronics, automotive, and aerospace industries to assemble particular complex products.

In projector-guided assembly, the projector is programmed to display images or diagrams of the product’s components and their correct assembly sequence. The worker follows these images to assemble the product using hand tools or automated equipment. The projector can also display real-time feedback, such as measurements or error messages, to help the worker ensure that the product is assembled correctly.

Projector-guided assembly is often used in conjunction with computer-aided design (CAD) software, which allows manufacturers to create detailed diagrams and instructions for the assembly process. This can help improve the efficiency and accuracy of the assembly process and reduce the risk of errors or defects in the final product.