Understanding and managing your electronics component inventory is crucial for any production scale. Neo Counter provides instant reel quantity insights and integrates updates directly into your ERP/MES/SCM or shop floor systems, ensuring seamless inventory management.

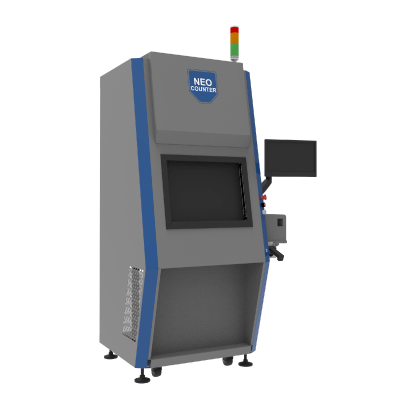

Neo Counter X400 changes the way of manual SMT component counting. The system comes with the latest X-Ray imaging and automation technology. Users can get SMD component quantity information in seconds.

The Neo Counter X800, an inline X-ray component counter, automates component counting with advanced features like batch processing, automation, material sorting, UID generation, printing, relabeling, and AGV/trolley handling.

X-ray counters scan reels with X-rays to count electronic components. They create an image analyzed by a computer for accurate counts. Ideal for precise tracking in manufacturing, these counters are more accurate than visual or weight-based methods, revealing hidden components.

Creating a beam of X-rays using an X-ray source, such as an X-ray tube or generator, to penetrate component reels.

Using advanced electronic detectors to capture X-rays that pass through the components and reel packaging.

Converting detected X-ray data into high-resolution digital images showing internal component structure.

Advanced software algorithms analyze images to count components, detecting shapes, sizes, and positions with precision.

Displaying accurate count results and integrating data directly into ERP/MES/SCM systems for inventory management.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Get component quantity information in seconds, dramatically reducing the time spent on manual counting and speeding up production planning.

Seamless integration with existing ERP/MES/SCM systems ensures real-time inventory updates and automated data management.

Count components without opening reels or packages, maintaining component quality and packaging integrity throughout the process.

Detailed tracking and documentation of component consumption helps with demand forecasting and supply chain optimization.

Discover how inline X-ray component counters are revolutionizing SMT inventory management and automation processes.

Read More>>

Learn about the key advantages of implementing X-ray component counting technology in your manufacturing operations.

Read More>>

Contact our experts to learn how Neo Counter can revolutionize your component counting and inventory management processes.