About Totech

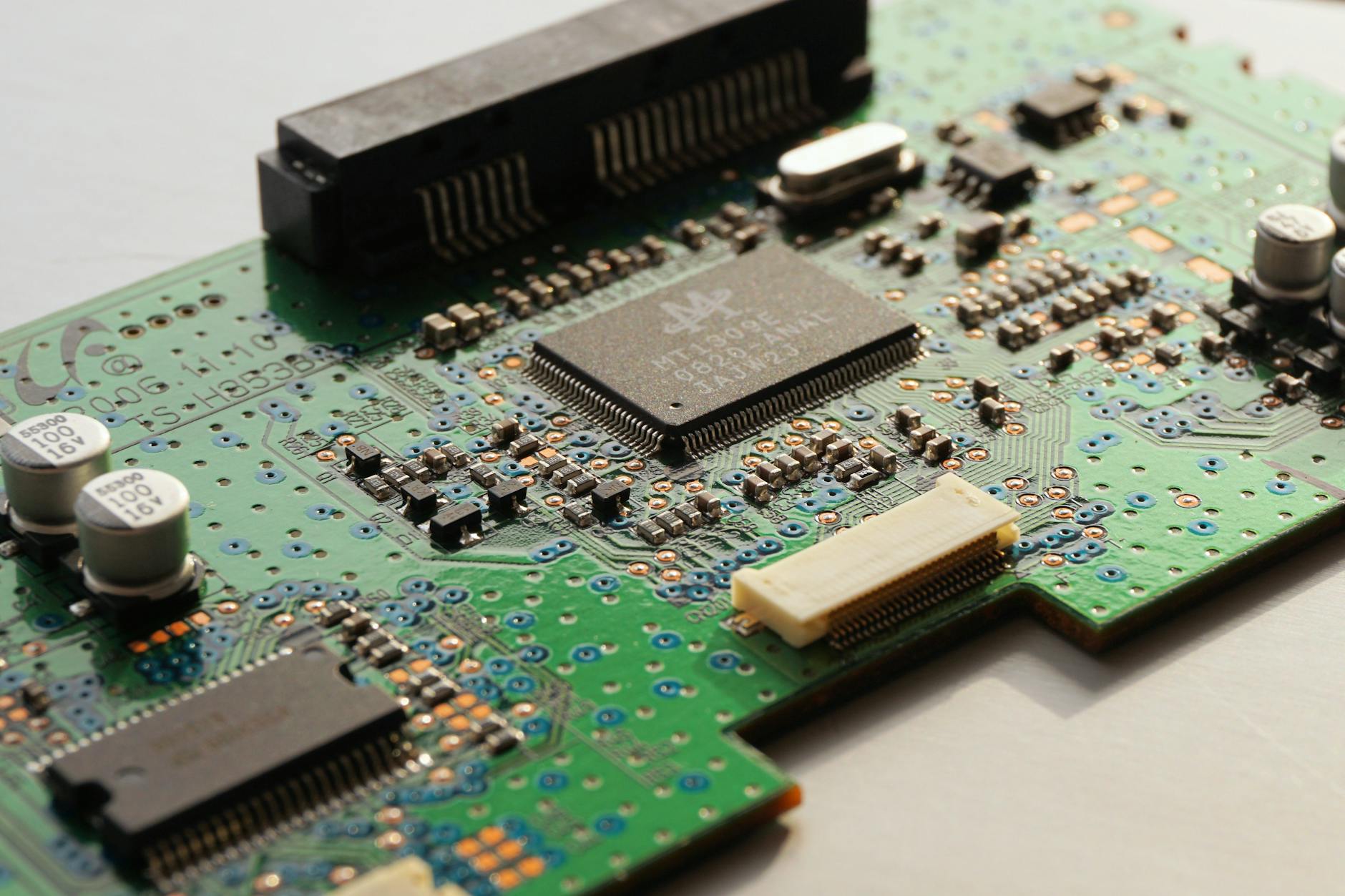

Totech specializes in handling and storage solutions for Moisture Sensitive Devices (MSD), offering a comprehensive range of dry storage solutions to maintain low, controlled humidity levels (<0.5%). Their products, designed to protect moisture absorbent materials such as electronic components, PCBs, nano fibers, and more, are vital in preventing water ingress and ensuring the integrity of sensitive materials. Totech’s global operations provide innovative solutions like desiccant dry cabinets, vacuum packaging, and the fully automated SMD warehouse logistics system, The Dry Tower. They also offer LTS² for third-party component storage and a “Dry Air Only” managed services solution for in-house moisture management without the overhead of owning and maintaining equipment. With a reputation for reliability and a broad customer base, Totech’s solutions are integral to various industries, including electronics, nanotechnology, and medical, by ensuring that storage issues are efficiently managed according to the highest standards.

Totech Dry tower

The Dry Tower from Totech represents a leap forward in the automation of SMD reel storage, offering a modular, low-maintenance solution with proven technology over two decades. It features a “H-Portal” positioning system, various handling options, and a flexible modular structure that supports multiple storage concepts. The Dry Tower’s design enables significant space savings and efficient materials flow management, with options ranging from manual trolley systems to fully automated conveyors and Autonomous Intelligent Vehicles (AIVs). This system not only simplifies the management of material logistics but also aligns with the aspirations of electronics manufacturers to achieve their smart factory goals under the umbrella of Industry 4.0. Totech’s Dry Tower automated storage systems underscore a commitment to innovative solutions that enhance the logistics and handling of electronic manufacturing materials.

Totech Software solutions

Totech offers a suite of software tools aimed at providing comprehensive control and oversight over moisture-sensitive inventories. These include:

- MSL 2.5 Software: This software facilitates the complete control of component inventory, offering features for real-time monitoring and the traceability of moisture-sensitive devices. It’s designed for seamless integration with existing ERP and MES systems, though it can also function as a standalone tool.

- Monitor Software: Aimed at real-time cabinet monitoring, this software comes with an optional alarm functionality. It’s compatible with SD+ and all Totech cabinets equipped with U-5003 and U-7203 Dry Units, as well as the Totech external datalogger, ensuring users are immediately alerted to any changes in moisture levels.

- Viewer Software: This tool is designed for cabinet monitoring with an integrated logger, standard across several Totech dry cabinet models including SD+, MSD, HSD, XSDB, XSD, and XSDV.

These software solutions underscore Totech’s commitment to providing advanced, user-friendly tools for the effective management of moisture-sensitive components. They cater to the needs of a broad spectrum of industries relying on precision in component storage and handling, further enhancing the operational efficiency and reliability of electronic manufacturing processes.