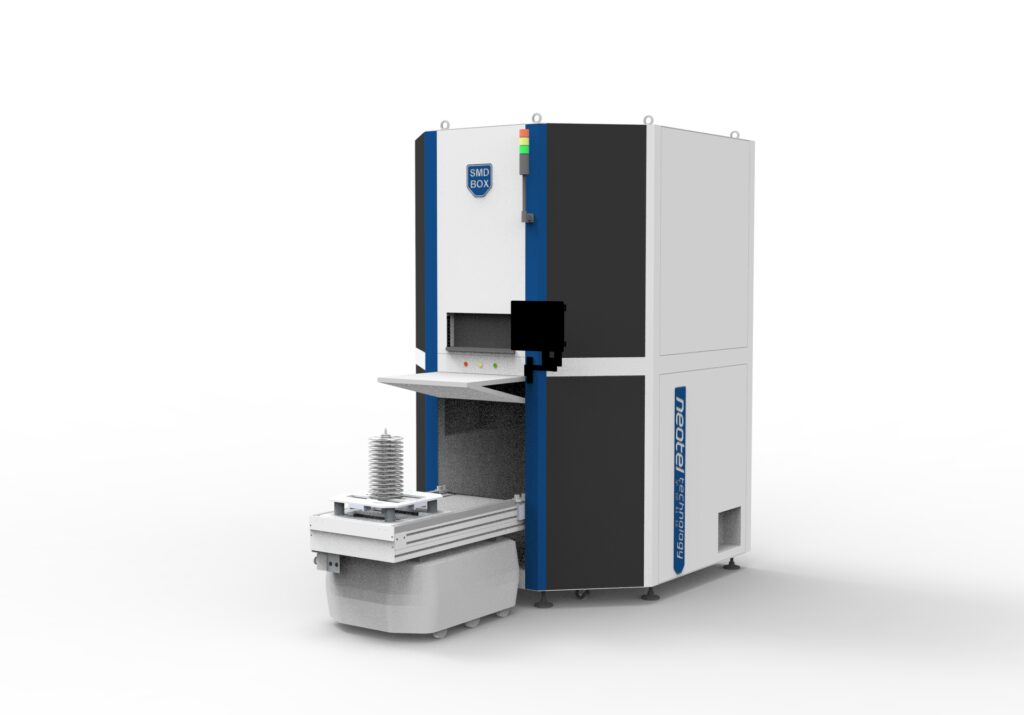

In the fast-moving electronics industry, every second and inch matter. Companies aim to boost operations, and the tech they use is vital. Managing SMT reels and tackling component shortages are now key in electronics making.This article contrasts Neotel Technology’s avant-garde SMD Box with the pallet based systems offered by Essegi Automation, underscoring the unique benefits of the former.

Direct Handling vs. Pallet based handling.

When comparing the Neotel SMD Box MIMO with the storage system from Essegi Automation., a key distinction is the method of reel handling. The Neotel SMD Box MIMO simplifies reel loading by eliminating extra steps and equipment. This direct approach enables users to immediately load individual reels into the storage system, enhancing efficiency and convenience.

Yet, Essegi’s system uses a pallet method for reels. First, users place the SMT reel on a pallet, then it’s added to storage. This extra step makes it less straightforward than Neotel’s method.

Challenges of Essegi Automation Storage system: Pre-loading and Post-unloading Steps

In pallet-based storage systems like Essegi’s, pre-loading and post-unloading are required. They greatly affect workflow in electronics manufacturing and storage.

Pre-loading:

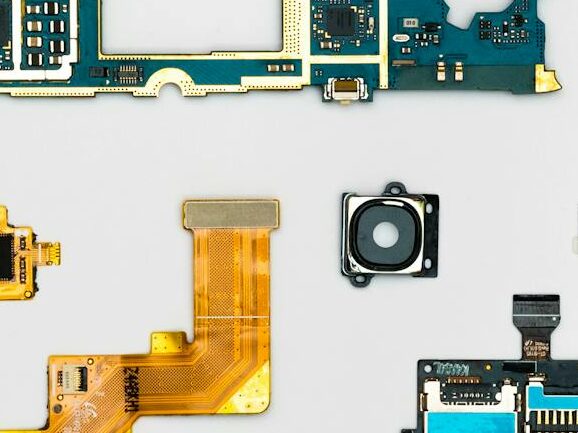

This step involves preparing the SMT (Surface Mount Technology) reels by placing them onto a pallet before they can be integrated into the storage system. This process requires manual handling and organization to ensure that the reels are properly secured on the pallets. It introduces an additional step in the workflow, requiring more time and labor before the reels can be stored.

Post-unloading:

After the reels are retrieved from the storage system, they must be removed from the pallets before they can be used in the production process. This step is necessary to access the individual reels for manufacturing or maintenance tasks. Post-unloading involves manually taking each reel off the pallet, which can be time-consuming and may delay the immediate use of the materials.

These steps contrast with systems like Neotel’s SMD Box MIMO, where reels are handled directly, allowing for immediate loading and unloading without the need for pallets. Direct handling streamlines the workflow by eliminating the extra steps of pre-loading and post-unloading, making it a quicker and more efficient method for managing reel materials.

The Paradox of Pallet Management: Storage Dilemmas and Manual Processes in Automated Systems

Integrating an automated storage system like Essegi’s introduces a paradox in the pursuit of efficiency and simplicity. Initially, users need to secure pallets for storing reels, either from the Essegi Automation or external racks. This step introduces concerns about material logistics even before entering the automated system.

Furthermore, after reels are unloaded from these pallets, another dilemma emerges: how to manage the empty pallets. Should they be returned to the Essegi system, or should they be placed on separate racks?

This situation creates a cycle of manual processes that seems at odds with the original intent of adopting an automated solution. Users find themselves navigating additional steps of pallet management, which introduces complexity and potentially undermines the efficiencies promised by automation. This paradox highlights the importance of considering the entire workflow, including auxiliary equipment and processes, when implementing automated storage solutions.

Challenges of Essegi Automation system in Sequenced Kitting

In electronics manufacturing, getting the right parts at the right time is crucial. This is where sequenced kitting comes in. It’s a process that ensures components, like SMT reels, are prepared and delivered in the exact order needed for assembly. Ideally, each reel is released one at a time, directly in line with the assembly work order and specifically matched to each feeder slot on the production machine.

However, when using pallet-based storage systems, this precise process hits a snag. The main issue is the need for human intervention. Workers must manually retrieve each reel from the pallet, which slows down the process and introduces room for error. This manual step makes it challenging to maintain the tight sequence required for efficient assembly. In short, while pallet storage might be good for organizing large volumes of components, it complicates the sequenced delivery of parts, essential for streamlined electronics manufacturing.

The Sin Of Waste

The seven types of waste, often referred to in Lean manufacturing, include:

- Overproduction: Producing more than demanded leads to excess inventory and costs.

- Inventory: Excess materials or finished goods tying up capital and space.

- Transportation: Unnecessary movement of materials increases time and costs.

- Motion: Wasteful actions by workers due to poor ergonomics or inefficient layouts.

- Waiting: Idle time between process steps due to delays or inefficiencies.

- Overprocessing: Adding unnecessary features or steps beyond what’s required.

- Defects: Errors or defects leading to rework, scrap, or customer dissatisfaction. Identifying and eliminating these wastes improves efficiency, quality, and profitability in any process or organization.

The challenges associated with pallet-based storage from Essegi Automation, particularly in the context of needing pre-treatment before materials can be sent to the production line and the difficulty in achieving Just-In-Time (JIT) delivery, could be categorized under a few types of waste, but they align most closely with Waiting and Motion.

Waiting:

Because materials cannot be directly sent to the production line without pre-treatment, there’s a delay (waiting) in the workflow. This waiting time is a form of waste since it does not add value and slows down the overall process.

Motion:

The additional steps required for handling and preparing the pallets involve unnecessary movement of materials and possibly people. This extra motion is inefficient and does not contribute to the value of the final product.

About Essegi Automation

Essegi Automation makes smart storage systems for electronics companies. It started from a need to improve how electronic parts are managed on assembly lines. The company has roots in a spare parts business from 1994 and gained experience from DVD distribution. In 2009, Essegi created its first automated warehouse system. This system uses a special way to handle parts in trays. Since 2013, with JUKI’s help, Essegi has been selling its solutions worldwide, making it easier to manage electronic components.