About Mycronic

Table of contents

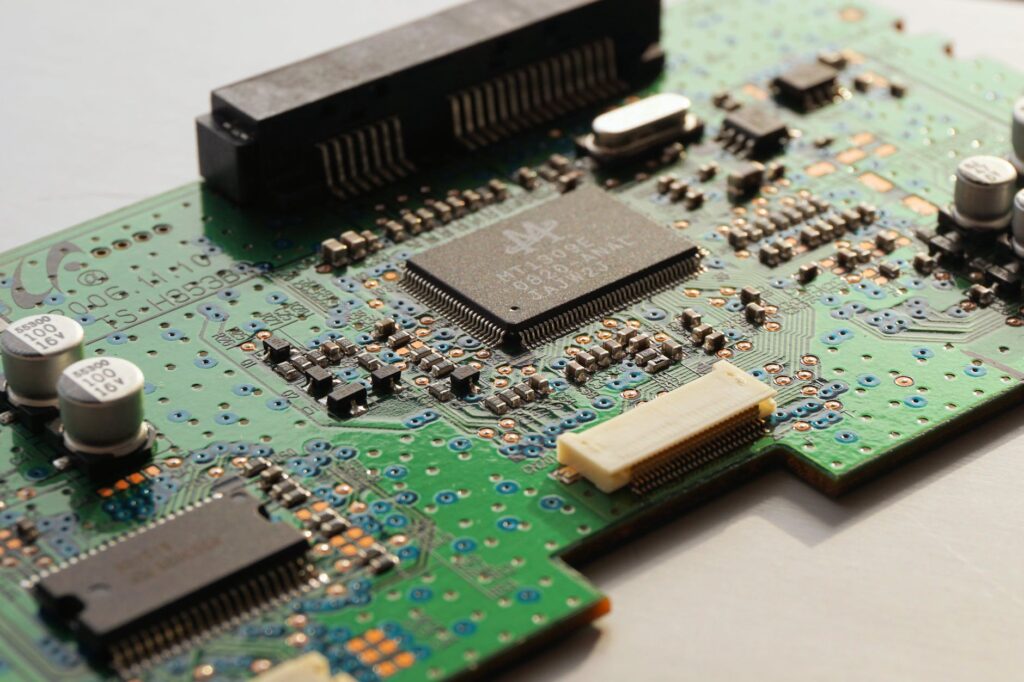

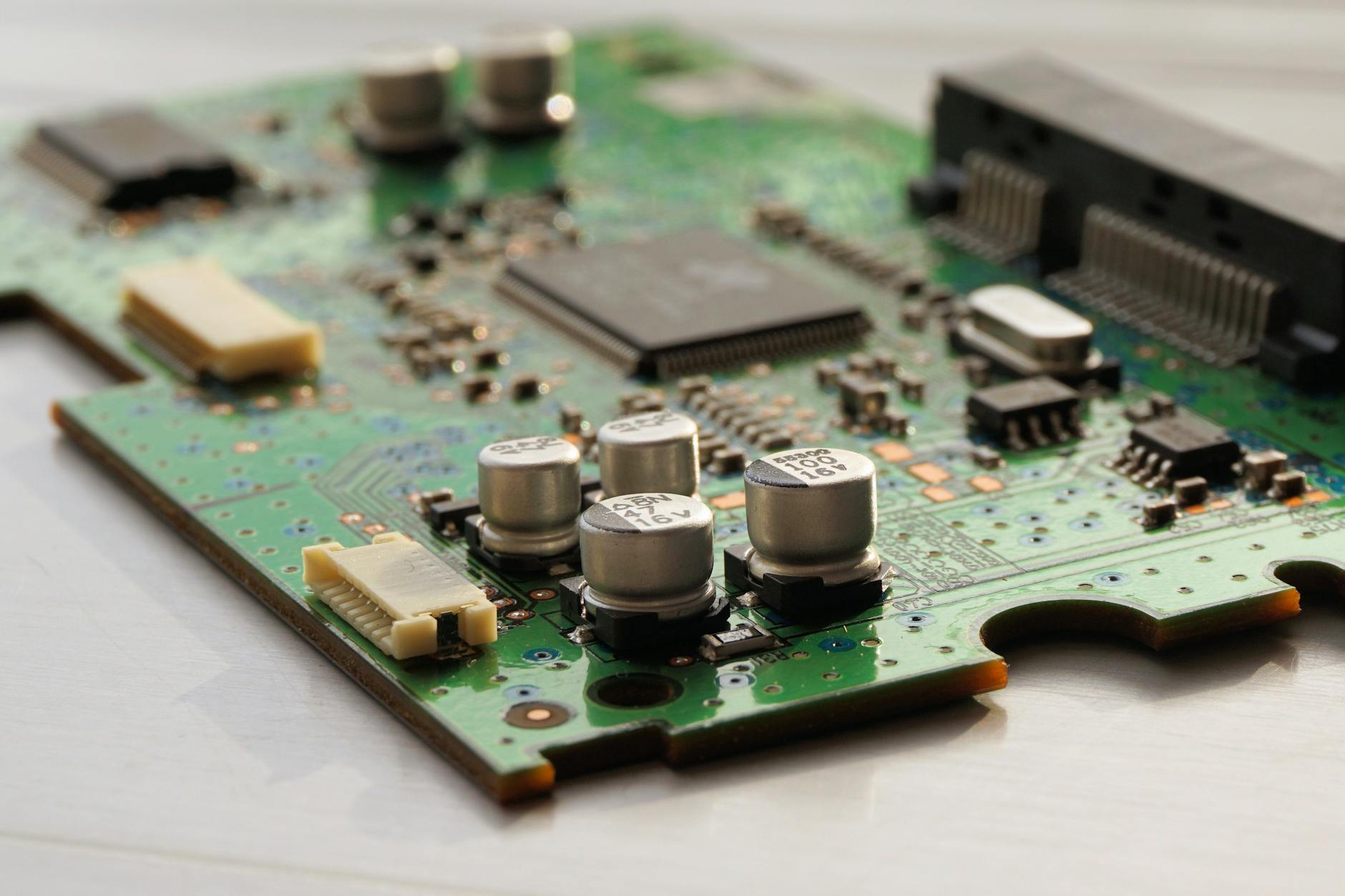

Mycronic is a renowned Swedish high-tech company that has carved a niche for itself in the electronics industry by developing, manufacturing, and selling advanced production equipment. Specializing in creating machinery that produces printed circuit boards, displays, and a wide array of electronic components, Mycronic sets the industry standard for precision and efficiency.

Products and Precision

At the heart of Mycronic’s offering is its lineup of production equipment, celebrated for its unparalleled accuracy and productivity-enhancing capabilities. This equipment plays a pivotal role in enabling the production of complex and high-quality electronic components, reflecting Mycronic’s commitment to innovation and quality.

MYTower

MYTower series, designed as automated, flexible, and expandable component storage systems tailored for PCB assembly environments. These towers are specifically developed to be deployed near production lines, optimizing space with their small footprint and enhancing the efficiency of SMT lines through a controlled material handling environment. The series includes various models like MYTower 5, MYTower 6, MYTower 6+, MYTower 7+, MYTower 5x, and MYTower 6x, each designed to meet diverse storage needs, from compact systems to high-capacity solutions accommodating a large quantity of reels. Mytower is working in the SISO mode.

Mycronic emphasizes the adaptability of these units, which are compatible with Agilis feeders, further facilitating quick and smooth changeovers. The storage systems are engineered for maximum reel storage capacity, even in locations with height constraints, showcasing Mycronic’s commitment to innovation and their dedication to extending the frontiers of electronics technology alongside their customers. This commitment is underpinned by their global presence, high precision production equipment, and a strong focus on customer collaboration.

MYTower 5 component storage

The most compact component storage solution in the Mycronic portfolio, ideal for environments with limited floor space and height restrictions. This model can hold a maximum of 812 reels and is versatile enough to accommodate reel sizes ranging from 4 to 15 inches, ensuring a broad applicability across various SMT (Surface Mount Technology) assembly requirements.

Key highlights of the MYTower 5 include:

- Compact Design: With a footprint of less than 1.5 m² and a height of only 2.26 meters, it’s designed for efficient space utilization.

- Flexible Storage: Tailored to store the most common component sizes used in the industry, offering flexibility in component management.

- Efficient Material Handling: The MYTower 5 revolutionizes SMT manufacturing by providing an automated solution for storing and retrieving reels, thereby minimizing physical search and retrieval time, and reducing space consumption compared to traditional storage methods.

- Accurate Component Tracking: Featuring a system that records every movement of the reels, ensuring accurate tracking of component quantities and locations. A unique identification code per component enhances precision in supply to the pick-and-place machines and storage, virtually eliminating mix-ups.

The MYTower 5 is positioned as a solution that not only maximizes storage efficiency in constrained spaces but also significantly improves the material handling processes in SMT manufacturing lines. By integrating seamlessly into existing material systems, it offers a streamlined approach to component storage and retrieval, marking a step forward in flexible, space-efficient storage solutions for the electronics manufacturing sector.

MYTower 6 component storage

The MYTower 6 by Mycronic represents a significant advancement in component storage solutions for the electronics manufacturing industry, particularly in the context of Surface Mount Technology (SMT) assembly lines. Boasting a capacity of 980 reels, it is designed to accommodate a wide range of reel sizes, from 4–13 inches to 15 inches, making it a versatile solution for various component storage needs. Despite its increased capacity — offering 20% more storage than the MYTower 5 — it maintains a compact footprint of less than 1.5 m², ensuring that it can be easily integrated into manufacturing environments with limited space.

The MYTower 6 not only provides flexible storage options but also addresses key operational challenges in SMT manufacturing, such as the need for efficient component retrieval and accurate inventory tracking. It closes the gap in flexible manufacturing by allowing for the automated retrieval of reels from a space-efficient system, thus eliminating the time and space costs associated with traditional storage methods. Additionally, its precise tracking system records every movement of the reels, ensuring accurate component quantities and reducing the risk of mix-ups. This level of automation and precision in component handling is designed to streamline manufacturing processes, reduce operational downtime, and enhance overall productivity in PCB assembly operations.

MYTower 6+ component storage

The MYTower 6+ represents a pivotal evolution in component storage solutions, specifically designed to cater to the needs of Surface Mount Technology (SMT) assembly lines in the electronics manufacturing sector. Retaining the compact footprint of less than 1.5 m², similar to the MYTower 6, this storage system distinguishes itself with the enhanced capability to store 15-inch reels in all of its magazines, making it a highly versatile and flexible storage option. With a capacity to hold up to 980 reels, the MYTower 6+ allows manufacturers to store any size of reel, addressing the diverse needs of modern electronics production environments.

This model underscores Mycronic’s commitment to innovative storage solutions that not only maximize space efficiency but also streamline the component retrieval process. By integrating seamlessly with existing material handling systems, the MYTower 6+ closes the gap in flexible SMT manufacturing, where traditional storage systems have fallen short due to their space-consuming and inflexible nature. Furthermore, the MYTower 6+’s precise component tracking feature ensures accurate inventory management, virtually eliminating the risk of mix-ups and facilitating quick and convenient returns to storage.

In essence, the MYTower 6+ is a testament to Mycronic’s forward-thinking approach, offering electronics manufacturers a storage solution that not only meets the current demands for flexibility and efficiency but also anticipates the evolving needs of the industry.

MYTower 7+ component storage

The MYTower 7+ by Mycronic stands out as the pinnacle of component storage solutions, specifically engineered for Surface Mount Technology (SMT) assembly lines. Marking its place as Mycronic’s tallest storage system, the MYTower 7+ boasts an impressive height of 3.03 meters, coupled with the capacity to store up to 1,148 reels. Despite its towering stature, it maintains a remarkably compact footprint of only 1.55 m², illustrating a commitment to space efficiency alongside storage capability.

Designed to be placed close to the production line, the MYTower 7+ serves as a near-production buffer that enhances operational efficiency by ensuring components are readily available when needed. This system is an answer to the electronics manufacturing industry’s call for a storage solution that combines high capacity with a minimal spatial requirement, offering a strategic advantage in optimizing production floor space.

Integration with existing material handling systems is seamless, underscoring the flexibility and adaptability of the MYTower 7+. The automated tracking feature guarantees that every component’s movement is recorded, drastically reducing the chances of mix-ups and facilitating swift returns to storage. This precise tracking ensures that the right component is always at hand for the pick-and-place machines, enhancing productivity and minimizing downtime in SMT lines.

The MYTower 7+ is a testament to Mycronic’s innovative approach to storage solutions in the PCB assembly sector, providing a sophisticated, space-efficient system that meets the high-volume storage needs of modern electronics manufacturing processes.

MYTower 5x component storage

The MYTower 5x emerges as a cutting-edge solution within Mycronic’s lineup of component storage systems, specifically designed to address the challenges of maximizing storage capacity while minimizing floor space usage in Surface Mount Technology (SMT) assembly environments. Perfect for facilities with height restrictions, the MYTower 5x boasts an unparalleled capacity to store up to 2,052 reels on a footprint of less than 2 m², making it the epitome of efficient space utilization in electronics manufacturing.

With a remarkable storage ratio of 1,057 reels per square meter, this system is tailored for storing large quantities of 7-inch reels, offering unprecedented flexibility and efficiency. Whether used as a main warehouse or as buffer storage close to the production line, the MYTower 5x adapts seamlessly to a variety of operational needs, enhancing workflow and reducing downtime.

Key features such as automated component tracking ensure accurate management of inventory, eliminating the risks of mix-ups and facilitating rapid access to necessary components. This contributes to a streamlined production process, optimizing the SMT line for greater productivity and effectiveness. The MYTower 5x represents a strategic investment for electronics manufacturers aiming to leverage space-saving innovations while maintaining high storage capacities.

MYTower 6x component storage

The MYTower 6x is Mycronic’s biggest storage system. It can hold 2,468 reels in under 2 m². This makes it perfect for places with little room. It’s as tall as the MYTower 6 and 6+, but stores more thanks to new tech. It works as a main or extra storage near production. It fits well with current systems and keeps track of everything to avoid mix-ups. This system is great for making more space and keeping track of parts in PCB production.

Comprehensive Customer Support

Beyond its hardware offerings, she is dedicated to enriching its customers’ experience through a comprehensive suite of services. These services include expert training, robust support, and meticulous maintenance programs, all designed to maximize the value and longevity of their investments in his equipment.