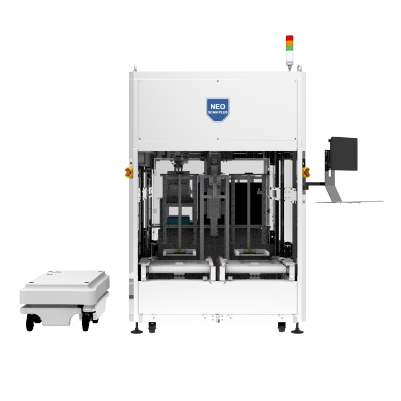

NEO SCAN PLUS is a fully automatic material registration workstation — AGV delivery, 11MP high-resolution vision for automatic barcode recognition, automatic UID generation, and automatic label printing and application. From material receiving to warehousing, the entire process runs unattended. Paired with SMD BOX, it creates a fully automatic material closed loop.

NEO SCAN PLUS operates at Step 1 of the SMT material loop — fully automatically generating a unique ID (UID) for every incoming reel. With this digital identity established, all subsequent storage, retrieval, counting, and return operations achieve precise tracking and intelligent scheduling.

NEO SCAN PLUS delivers a 5-step fully automatic registration workflow. From AGV delivery to material warehousing, no manual intervention is required, supporting 24/7 unattended operation.

NEO SCAN PLUS covers six dimensions — automatic recognition, automatic labeling, AGV integration, material sorting, traceability management, and system integration — providing a complete solution for fully automatic material registration.

NEO SCAN PLUS features an industrial-grade 11MP vision system and AGV integration interface, purpose-built for large-scale fully automatic material registration scenarios.

| Parameter | NEO SCAN PLUS Specification |

|---|---|

| Vision System | 11MP high-resolution industrial camera + AI deep learning recognition algorithm |

| Work Area | 400 x 400 mm scanning area, accommodates all common reel sizes |

| Printing System | Industrial barcode printer, supports PET, high-temperature, and various label materials |

| Scanning Capability | QR, Datamatrix, Code128, and full 1D/2D barcode format support |

| UID Generation | Automatic UID issuance, EIA-564 compliant, full lifecycle traceability |

| AGV Interface | Dedicated AGV intake port, supports batch reel-chain delivery, 24/7 unattended |

| Software Platform | SMF Smart Material Control Platform (work order management, MSD tracking, material traceability, IoT hub) |

| Interface Protocols | RESTful API / Direct SQL / Webservice — three integration modes |

| Power Supply | AC 220V / 50Hz, industrial-grade ESD-safe design |

Once NEO SCAN PLUS completes registration, materials enter the next stage of the fully automatic ecosystem. Data flows through the UID at every step, enabling end-to-end traceability.

Common questions about the NEO SCAN PLUS fully automatic material registration system. For further inquiries, please contact our technical consultants.

NEO SCAN PLUS fully automatic scan-label-register system delivers end-to-end unattended operation from AGV delivery to warehousing. Contact us today for a tailored full-automation registration solution.