Streamlining assembly lines: How digitalization is changing the game for through-hole component assembly

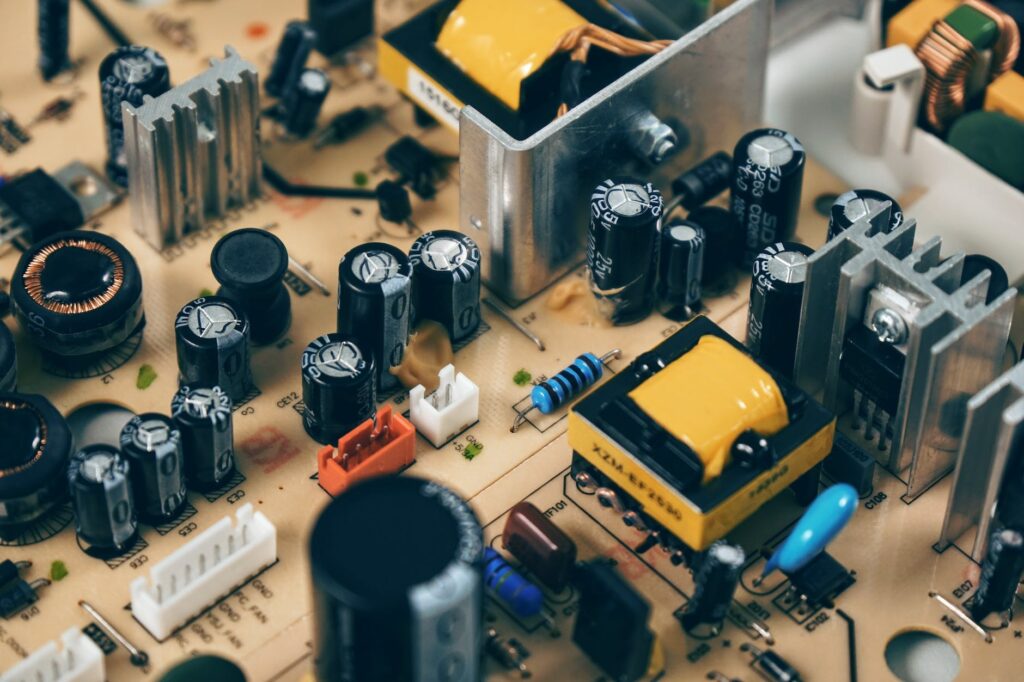

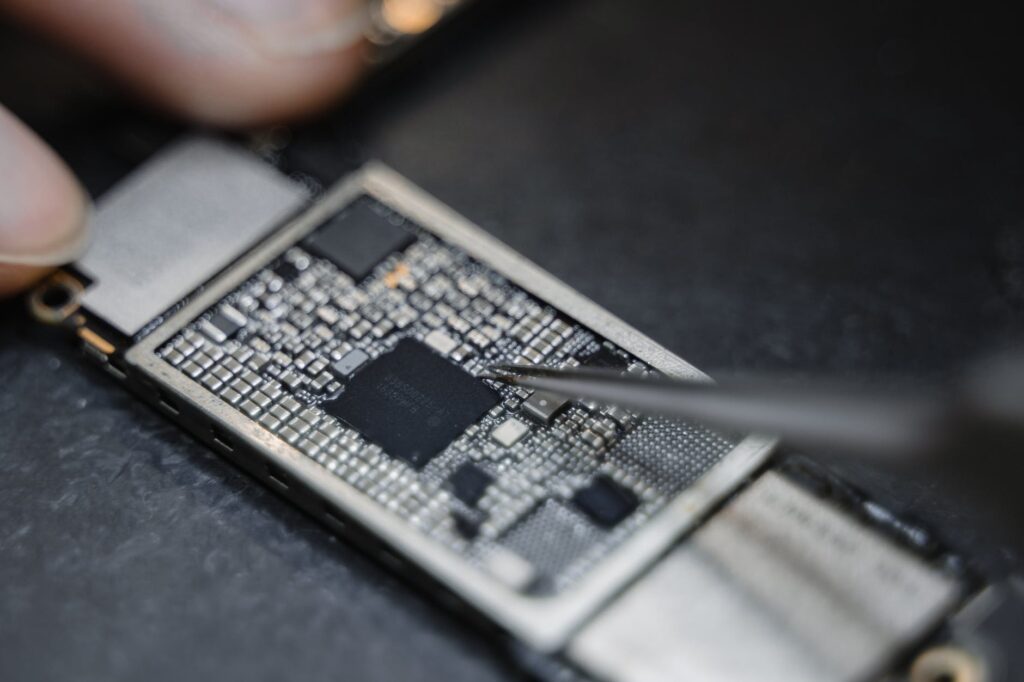

Manual through hole assembly risks and challenges Manual through-hole technology, darling, is a quaint method of assembling electronic devices. It involves manually inserting components into holes drilled in a printed circuit board and then soldering them. It’s like fitting puzzle pieces together, only with a soldering iron. The main challenge with this technique is the […]

Top 10 benefits of using smart storage system

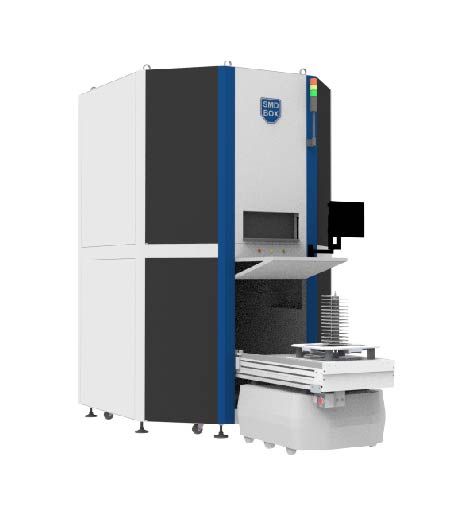

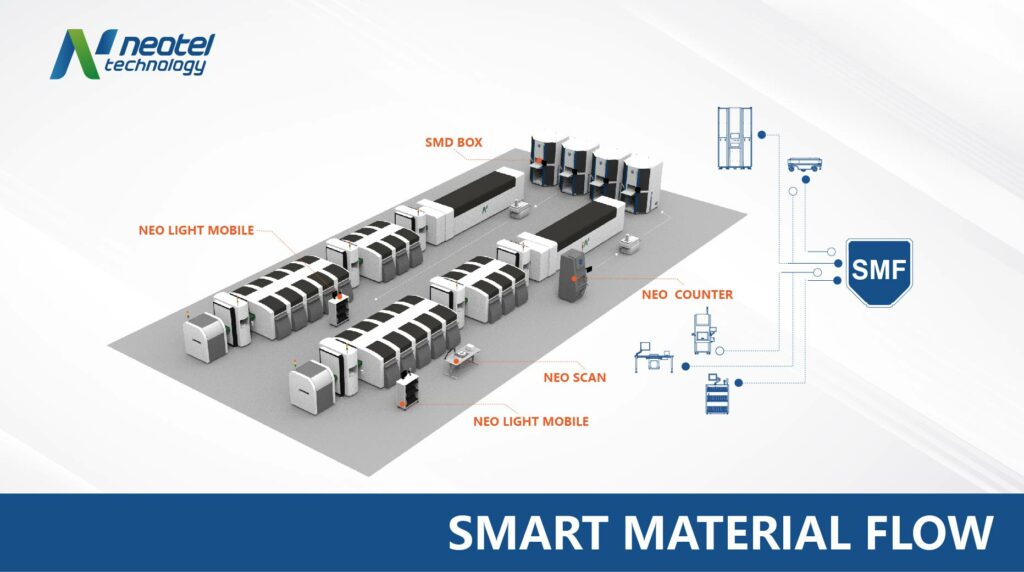

SMT smart storage system Smart storage systems are an essential part of modern PCB assembly processes, as they allow manufacturers to efficiently store and access the many different types of components that are used in these assemblies. SMT storage systems may be used in a variety of settings, including electronics manufacturing plants, prototyping labs, and […]

What is Inventory?

While we often discuss inventory in terms of goods for sale, organizations – manufacturers, service-providers also have inventories (fixtures, furniture, supplies, etc.) that they do not intend to sell.

5 reasons to automate your SMT storage

Neotel SMD BOX is a combination of equipment and controls that handle, store, and retrieve materials with precision and speed driven by varying levels of automation. Systems range from single module automated systems to larger storage/retrieval systems, completely integrated into a manufacturing process. Why to automate SMT storage? 5 Reasons! 1. Optimize space Probably the greatest […]

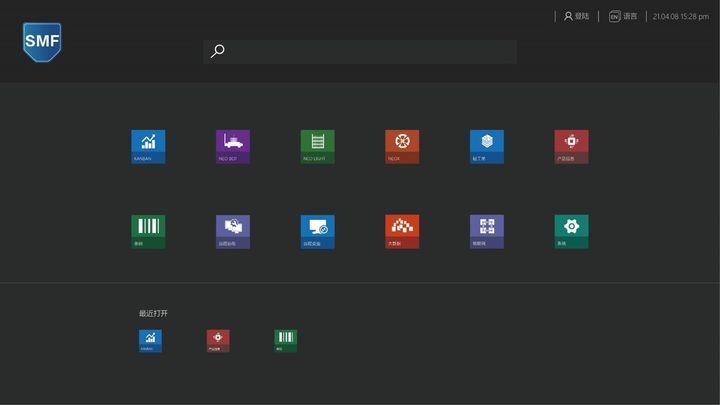

Six things about MES

What is an MES? An MES (Manufacturing Execution System) is a management-level tool used by manufacturers to monitor and control the transformation of materials into finished goods. By incorporating an MES into their operations, manufacturers gain complete visibility into a variety of production silos. This includes: Resource and material usage Production output Quality control Labour/workforce […]

6 things about smart inventory control in SMT industry

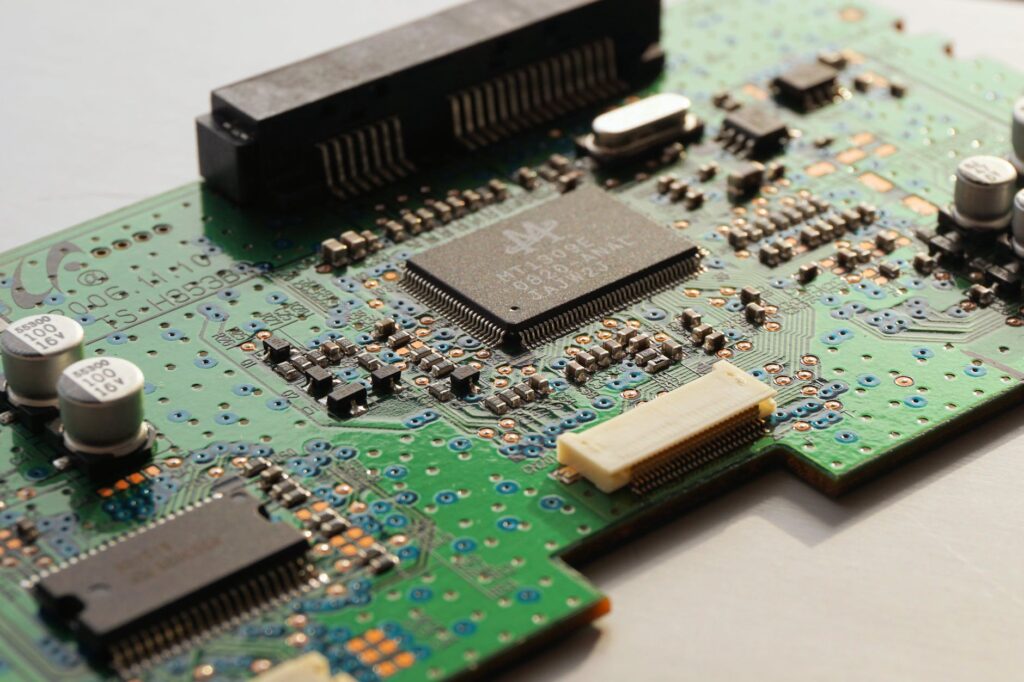

Inventory control in electronics manufacturing industry involves managing inventory (also known as stock) from the time it lands in the warehouse to the time it leaves. Good inventory control can ensure reliable production, frees up organization resource by keeping stock levels low – while avoiding running out altogether.

How SMT smart rack work?

Smart rack in SMT industry usually means reel rack systems use light indicator modules mounted to shelving. Whenever product is needed from a particular SMT production, the right indicator turns on, drawing attention where action is required. The operator picks the needed electronics components quantity required in job list/work order. After picking, smart rack can then detect the component removed and update inventory information to WMS or other inventory management system.

SMT reel: 5 things you should know

What is SMT reel? SMT stands for Surface Mount Technology.SMT reel is a spool of material, usually made of plastic or cardboard, that is used to hold and dispense a material such as a wire, cable, or component. In the context of SMT, a reel is often used to hold and dispense components that are […]

How to store your electronic components?

There are a list of question in front of you before decision making: Floor space utilization. Labor costs vs. investment Real time inventory control Material throuput Smt reel and tap MSL control System integration to existing IT structure ESD safe Storage cart ,dry box, SMD rack, reel shelving or intelligent SMD storage system, and many […]

Top 4 benefits of Enhanced Pick to Light systems

Top 4 benefits of Enhanced Pick to Light system