Economia a zero emissioni

Il cambiamento climatico sta influenzando drasticamente il settore della produzione industriale globale e i leader del settore manifatturiero stanno rispondendo alla sfida. Investendo in strategie sostenibili come i green collar jobs e adattandosi al cambiamento, possiamo migliorare il quadro che abbiamo costruito per la produzione e lo scambio globale. Gli spunti per questo argomento provengono […]

Net-Zero Economy

Climate change is drastically affecting the field of global industrial production, and manufacturing leaders are responding to the challenge. By investing in sustainable strategies like green collar jobs and adapting to change, we can improve upon the framework we have built for global production and exchange Insight for this topic comes from Green Collar Jobs, […]

Economía neta cero

El cambio climático está afectando drásticamente al ámbito de la producción industrial mundial, y los líderes de la industria manufacturera están respondiendo al desafío. Invirtiendo en estrategias sostenibles, como los empleos de cuello verde, y adaptándonos al cambio, podemos mejorar el marco que hemos construido para la producción y el intercambio mundiales. La información sobre […]

Mixed-Model Assembly

What is Mixed-Model Assembly? Mixed-Model Assembly is a type of production system that produces several distinct products or models within one operation without decreasing productivity, efficiency, and quality. Within these environments, the number of products built on one line can reach up to hundreds of thousands of variations. The frequency and specifications of the models […]

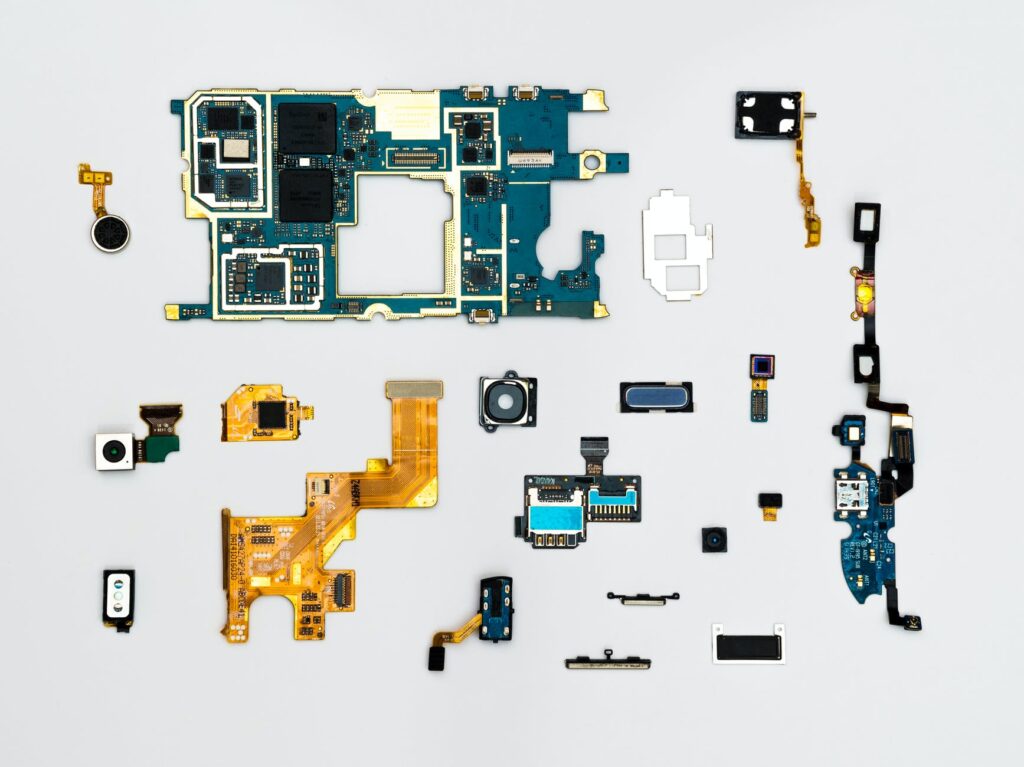

Material Requirements Planning (MRP)

What is Material Requirements Planning (MRP)? Material Requirements Planning is an inventory management system that helps businesses plan, track, schedule, and monitor their manufacturing processes and material usage more efficiently. MRPs typically have 3 main goals: Assure that production always has access to the required materials and components.Keep the lowest material and component levels possible […]

PDCA Cycle

A staple of any variation of institutional quality control methodology, the PDCA Cycle is a simple yet effective tool to plan and differentiate the steps of continuous improvement on a per-project basis. The PDCA Cycle is an iterative tool that is commonly used in the Six Sigma and Total Quality Management business philosophies. KEY TAKEAWAYS […]

Pareto Principle

What Is the Pareto Principle? Have you ever heard of the 80/20 rule? It is the phenomenon that 80% of consequences come from 20% of causes. This principle can be seen in action across multiple areas of study like ecological environments, societal structures, work time management, and even language. To wrap our minds around it, […]

Personal Protective Equipment (PPE)

What is PPE? PPE (Personal Protective Equipment) is considered to be any article of clothing or wearable equipment that shields and/or protects a person from injury. This includes reflective vests, hard hats, safety glasses, hazmat suits, and more than we can list. Accidents and mishaps are inevitable factors within our daily lives. From working on […]

Poka Yoke

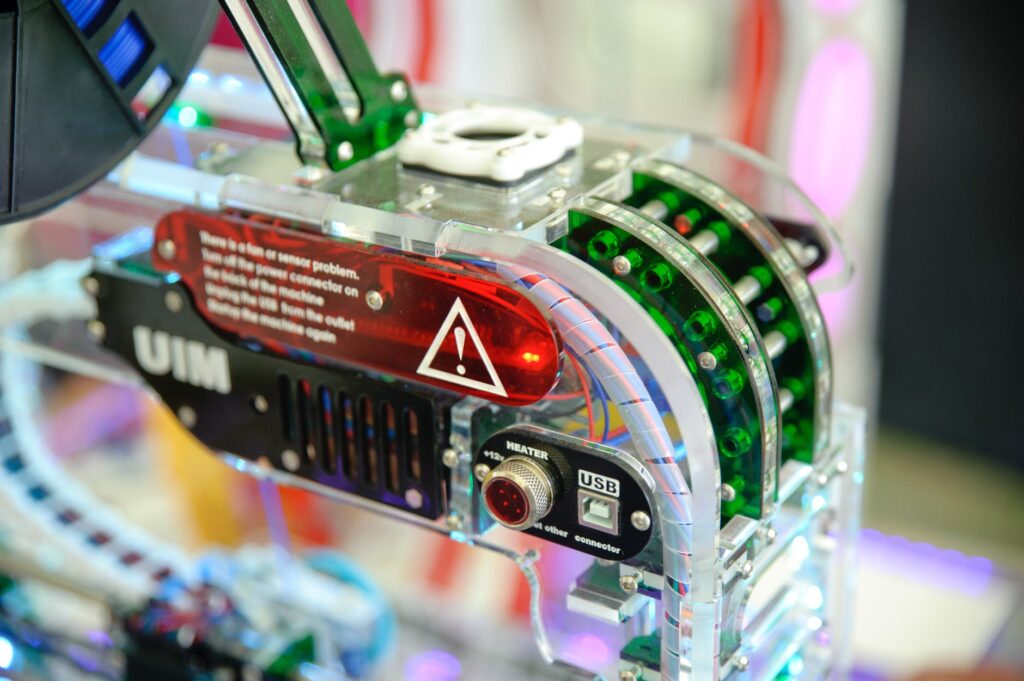

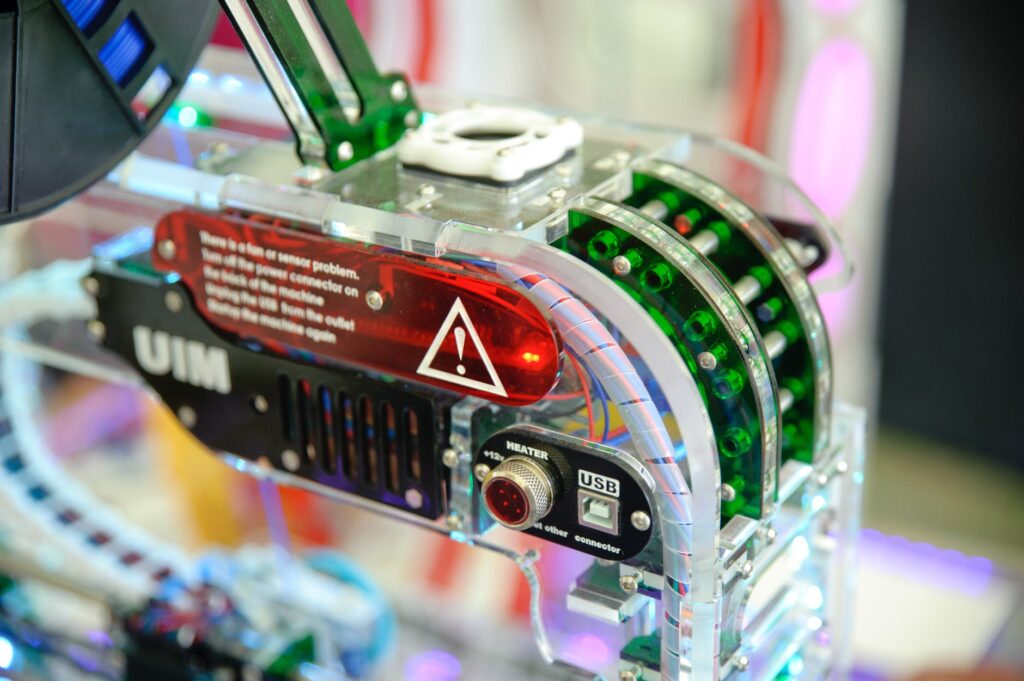

Poka yoke is a Japanese term that means “mistake-proofing” or “error-proofing.” It is a quality control method that aims to prevent mistakes or errors from occurring in the first place by designing processes and systems in a way that makes it difficult or impossible for mistakes to happen. The concept of poka yoke was developed […]

Productivity Monitoring

What is Productivity Monitoring? Knowing how productive your employees are is good. But being able to collect data and use it to optimize your production is nothing short of excellent. Productivity monitoring helps people track their goals and understand the inner workings of their operations while empowering workers through engagement. This is done by: Tracking […]